Air pressure tests are made to check for any leak in tubes. The final goal is to guarantee tubes following given standards. Therefore, air pressure test are designed to check for a certain size of defect. Calculations are made to know the pressure level and the holding time necessary in order to guarantee the tube.

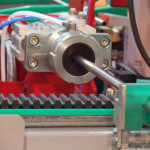

The station is composed of a fixed head and a mobile head (settings for tube length adaptation). The tube is positioned on the bench and caught by jaws. Testing heads translates to reach both tube ends. Pressure rise, holding and decrease are controlled with a leak detector system designed for high accuracy measurement. If the pressure measured overtakes a given delta, the tube is refused and will be ejected in a specific storage.

Once again, several versions are available – air pressure test benches are fully adaptable to customer demand (simultaneous tube tests to increase production pace, automation of holding time from the workstation…and so on).

English

English